An enquiry from Total E&P UK resulted in a new plug system being designed, manufactured and tested for ROV use over one weekend in October by Miko Marine.

The plug was needed by DeepOcean UK to seal a grey water sea outlet on the Gryphon FPSO located 110 miles north east of Aberdeen. Miko’s existing range of plugs had been designed for use by divers so, because the plug had to be fitted by ROV, a new solution was needed quickly. The design proved so successful that it is has now been registered as The Miko Speed Stopper and is currently being streamlined for regular production.

It was a video conference with Total and Miko engineers that resulted in a design which straddled the defective outlet with a stainless-steel beam connected between two high-power magnets. Once placed in position by the ROV, the seal could be screwed down from the centre of the beam to clamp tightly over the outlet from the leaking valve. With the design finalised on the Saturday, engineers in Miko’s production facility at Haugesund, Norway, had time to manufacture and test the unit so it could be delivered to Total for Tuesday.

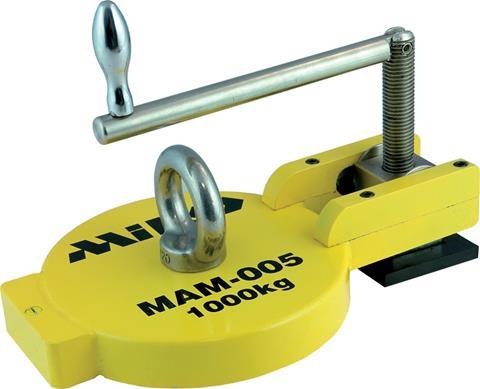

The permanent Miko magnets used were all fitted with modifications which made them easy to operate with an ROV manipulator claw. The two magnets used at either end of the stainless-steel beam were Miko MAM 005 units which each have a holding force of 1000 kg and ensured that there was no fear of them lacking the power to guarantee a tight seal even against a high pressure outflow. A third magnet chosen from the top of the Miko MAM magnet range had a holding force of 2000 kg and was used as an anchor point for the work class ROV while it was fitting the seal. Once the valve had been replaced it was a simple matter for the ROV to turn the release handles on each of the magnets so they could all be recovered and stored aboard the Gryphon for future use when required.

Commenting on the success of his company’s innovation, Cato Stoll, managing director of Miko Marine said; “Because much of our work is concerned with the salvage industry, we are used to responding instantly and travelling to anywhere we are needed. It was particularly satisfying to successfully complete an urgent job and realise that we had, at the same time, created a new tool suitable for numerous uses offshore. The unit supplied to Total was basically a prototype but following some minor design tweaks we are now able to offer the marine and offshore industries a very useful product. From the customer’s point of view the Speed Stopper also provides the added benefit of providing two powerful MAM magnets that can be detached from the unit and be used for countless other tasks above or below water if required. I am particularly proud that we employ some very highly qualified engineers and naval architects who have been recruited for their creativity and innovative thinking. They enable us to react quickly and find solutions to difficult problems across a broad range of technical disciplines.”

Miko Marine has many years of experience in working with powerful permanent magnets for use at sea and on-shore. The company is fully conversant with the technical demands imposed to ensure their safe transportation and usage. Miko also produces a range of magnetic patches that are in use around the world to provide emergency seals for vessels that have suffered hull damage. Miko Plasters – as they are called – can ensure that a vessel remains afloat and is sufficiently seaworthy to make a journey to the nearest repair yard without the need for expensive and difficult underwater welding, and can also be used as a DNV qualified tool for blanking of seawater inlets during in water repair.