The UK’s leading marine power and electrical engineering specialist - MJR Power and Automation - has successfully completed a major life extension project for a Tees dredger that will see the ship continue to operate safely for the next 15 years.

Headquartered in Stockton-on-Tees, MJR Power and Automation has delivered the complete electrical power, propulsion, dredging and automation system upgrade on the trailing suction hopper dredger Heortnesse, operated by PD Ports.

Awarded by the UK’s largest commercial ship repair and conversion specialist, A&P Tees, the contract required an experienced company to deliver the complex scope of works within an aggressive timescale for the dredger’s life extension project.

Under challenging restrictions, due to Covid-19, MJR Power and Automation successfully delivered a full turnkey solution from design, engineering, and construction through to installation and commissioning.

This included the main and auxiliary propulsion variable speed drives with two x 1.5MW and 500kW respectively, a 1.2MW dredging pump variable speed drive, a new bridge navigation with dredging consoles and power management system, all fully integrated into MJR Power and Automation’s innovative automation platform.

Through removing the previously manual and labour-intensive operating process, the upgrade has significantly increased the vessels efficiencies whilst also significantly enhancing safety of both personnel and operations.

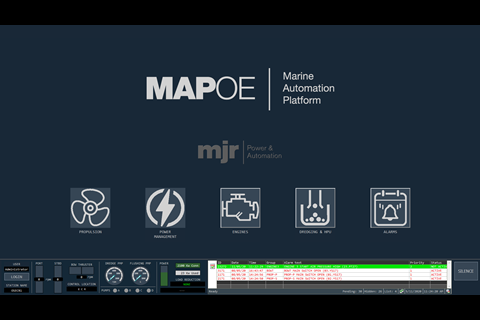

At the heart of the system is MJR Power and Automation’s proprietary Marine Automation Platform, MAP-OE™ installed for integrated machinery automation and control. This unique solution, built with commercially off the shelf hardware, provides high levels of redundancy and automation providing PD Ports with advanced machinery diagnostics, alarms and continuous condition monitoring. This can be accessed remotely through a secure VPN tunnel mitigating the need for onsite intervention, greatly reducing both time and cost of repair.

Speaking about the contract, Paul Cairns, Managing Director at MJR Power and Automation said: “We are delighted to have successfully completed this project that will see the Heortnesse operate safely and efficiently for at least the next 15 years.

“Designing and retrofitting complex marine systems of such scale, and with many levels of complexity - such as this project - required a company with extensive experience and a solid reputation in the field. This is where we were able to demonstrate our proven track record in delivering similar projects in both scale and complexity, to position MJR Power and Automation as a natural fit to deliver this major vessel infrastructure upgrade project.

“With such tight timescales there was absolutely no margin for error and getting the job done right first time was critical. And this is exactly what we are well known for in the industry – and have once again successfully achieved this.”

Engineering and construction were carried out at MJR Power and Automation’s Teesside facility, including full design approval by Lloyds Register of Shipping with system build and Factory Acceptance Testing (FAT).

Over a six-week period, and in the midst of the Covid-19 pandemic with restricted working conditions and access, the company safely disconnected, removed, replaced and installed all power, electrical and automation equipment at A&P’s Tees Dock Yard located at Teesport Commercial Park.

Remote access, inbuilt into the system, enabled MJR Power and Automation’s engineers to support the commissioning phase from its hub in Teesside and respect the project schedule which otherwise would have been impossible with the new site working restrictions.

Paul added: “The project has been completed under difficult circumstances as businesses adapt to a new way of working. We ensured all safety procedures were followed with staff socially distancing at all times and we still managed to meet the project deadline, despite work restrictions in place, which in itself is a great achievement. “

“The extension project has been completed by a number of companies located in the North East of England, who have all really pulled together to meet the complex needs in extending the life of the dredger”

“It is a great example further demonstrating the capability and capacity for businesses in the region to deliver major marine, offshore and renewable projects to the very highest standards.”

Operating for over 25 years in the marine, offshore and energy sectors, MJR Power and Automation is a leading specialist in marine power, electrical and automation engineering and provides complete end to end complex projects from design, engineering and construction to installation, commission and worldwide service from its headquarters in Teesside. The business has completed a number of recent high profile projects for global leading brands. Its impressive client portfolio includes the likes of Subsea 7, Van Oord, TechnipFMC, CalMac, Condor, Stena and P&O Ferries to name but a few.