Across the offshore energy sector, operators rely on diesel-powered equipment to deliver essential power, air and heat in some of the world’s most demanding environments.

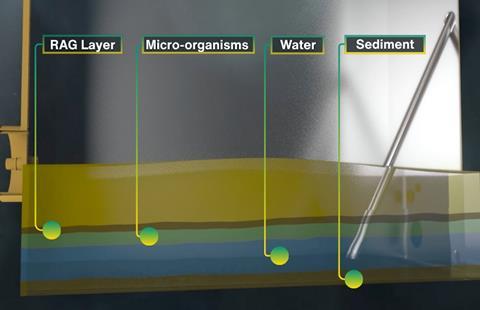

But in regions where fuel quality varies and storage conditions are unpredictable; contamination remains a major threat to engine health. Water, particulates and microbial matter settle naturally at the bottom of fuel tanks—exactly where conventional fuel pick-ups draw from—leading to premature wear, rising maintenance demands and costly unplanned downtime.

To address this, offshore rental specialists, including Centurion and Atlas Copco, have turned to FuelActive’s innovative fuel delivery technology to protect their fleets and improve reliability across global operations.

A Technical Step Forward in Fuel Delivery

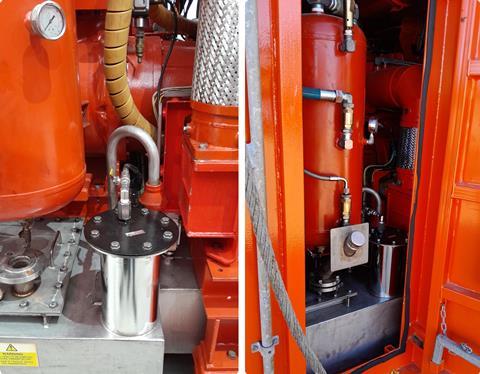

FuelActive replaces the traditional bottom-suction fuel pick-up with a patented floating pick-up system. Instead of drawing fuel from the lowest point in the tank—where contamination concentrates—the unit uses a buoyant chamber connected to the fuel line. This chamber continuously floats just below the surface of the fuel, ensuring that the engine draws from the cleanest, least contaminated layer.

Because contaminants are heavier than diesel, they naturally settle downward. By accessing only the upper, cleaner fuel:

- Water and heavy debris remain at the bottom of the tank

- Particulate being pulled into filters is significantly reduced

- Injectors and pumps are protected from abrasive wear

- Engines receive consistently cleaner fuel, even in challenging environments

The system is mechanical, with no electronics, sensors or moving parts that could fail. Its simplicity makes it highly versatile and easy to integrate into both deep and shallow tanks across a wide range of equipment.

|

|

|

Reliable Performance Across Offshore Applications

FuelActive has been deployed in generators, air compressors and other diesel-driven assets supporting offshore operations. Installations have been completed quickly at onshore service hubs, enabling operators to return equipment to service with minimal disruption.

Across multiple rental fleets, the technology has delivered:

- Up to four times longer fuel filter life

- Zero fuel-related breakdowns during extended operational periods

- Reduced maintenance callouts, especially in remote or harsh environments

- Extended engine and component life

- Lower fuel consumption and reduced CO₂ emissions through more efficient combustion

One fleet manager at Atlas Copco noted “FuelActive has enhanced the reliability of our offshore equipment. It consistently protects engines, whatever region we operate in.”

Another from Centurion reported: “By eliminating contamination at the source, we’ve removed a major cause of breakdowns. The improvement in uptime has been significant.”

Supporting Offshore Reliability From the North Sea to Southeast Asia

Whilst results vary by application, the pattern is consistent: operators experience much greater reliability, longer service intervals and improved environmental performance, with a return on investment in less than a year. Many fleets are now integrating FuelActive as a standard specification to safeguard high-value assets and reduce total cost of ownership.

With proven performance across regions including the North Sea, West Africa, the Middle East and Asia, FuelActive continues to play a central role in strengthening fuel integrity and ensuring uninterrupted operations in the offshore energy sector.

About FuelActive

FuelActive is a global engineering innovator dedicated to improving fuel efficiency, reducing emissions and enhancing engine reliability. Its patented floating fuel pick-up system delivers fuel that is up to 92% cleaner than conventional methods by drawing fuel from the top of the tank instead of the contaminated bottom. This simple yet transformative technology helps operators cut CO₂ emissions, reduce fuel consumption and prevent costly fuel-related failures.

Trusted by leading OEMs worldwide, FuelActive systems perform in some of the harshest working environments across construction, mining, agriculture, power generation and transportation. From its headquarters and Technology Centre in Cardiff, UK, the company supports customers on six continents through a growing international distributor network.